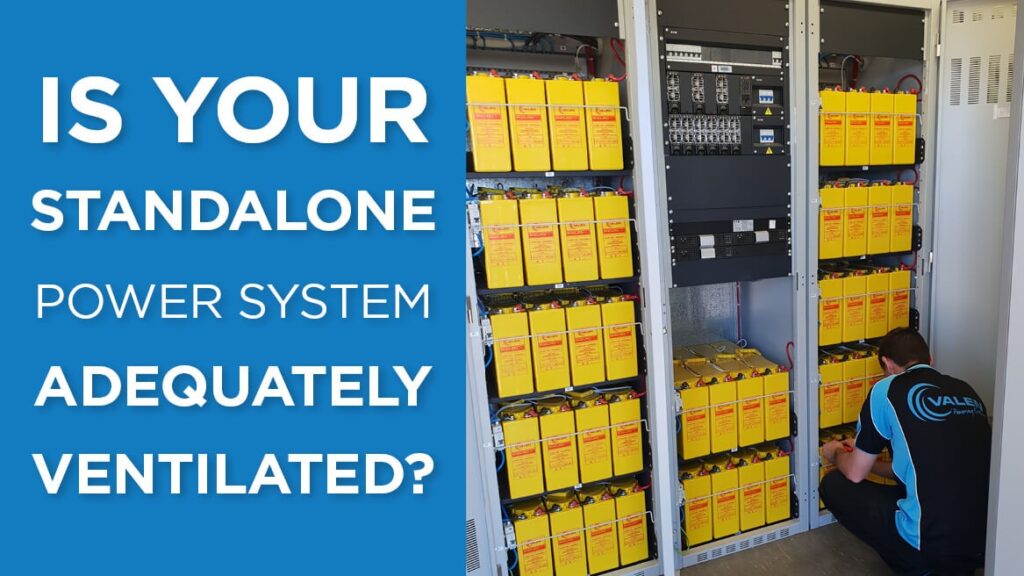

Gassing & Ventilation of Lead-acid Batteries in Standalone Power Systems. In secondary standalone power systems, the Team at Valen have often been asked the question as to what is required when it comes to gassing and adequate Ventilation.

In this blog, the Valen team outlines how to calculate and ensure that your standalone power system is adequately ventilated.

Battery Ventilation

Valve Regulated Lead Acid (VRLA) and Wet Cell (Flooded) battery types require Ventilation either by natural or forced methods.

This Ventilation is needed as the battery cells generate hydrogen and oxygen during their charging and cycling. In addition, boost, overcharging, or high temperatures can result in the additional release of hydrogen gasses from the battery.

Catalyst Life Extender Reduces Gassing

Standard VRLA Battery technology reduces the gassing by at least 80% over the standard flooded battery cells. You can also further reduce the gassing by Installing a Catalyst Life Extender to a VRLA battery, which reduces the amount of hydrogen gas emitted from the battery – See the Valen ENDUROGEL range for more details.

These Catalyst vents are designed to release a certain amount of gasses to allow the battery to vent when subject to extreme pressure; however, they recombine up to 80% of gasses that try to escape during normal operation.

A Catalyst Life Extender allows batteries to have the same life when operated at a higher temperature of 30 degrees; this is especially prevalent, bearing in mind that any 5degree increase above 20 degrees halves the life of the battery.

optional gassing system

Valen Front terminal Battery ranges have an optional gassing system whereby they can be tubed together and externally vented.

Reach out to the Valen team to discuss this option for your battery system

manufacturer’s Installation & Operating instructions

It is essential to follow the manufacturer’s Installation and Operating instructions. The charging system characteristics must be adhered to ensure minimal gassing or venting from the battery cells.

AS4086.2-1997 clause 2.7.2* states, ‘ The average hydrogen concentration by volume in a battery enclosure shall be maintained below 2%.’

Forced & Natural Ventilation

As mentioned earlier, there are two forms of Ventilation, Forced & Natural Ventilation.

Forced Ventilation

Forced Ventilation may be by exhaust fans, air conditioning, etc. However, it is recommended that natural Ventilation is used as there is less chance of failure.

Where Forced Ventilation is utilised, an airflow sensor should be installed to initiate an alarm should the source of Ventilation become inoperative.

The following equation can calculate adequate forced Ventilation:

qv = 0.006nI . . . 2.7.3

where

qv = the minimum exhaust ventilation rate, in litres per second

n = the number of battery cells

I = the charging rate, in amperes (see Clause 2.7.4)

If there is more than one battery in an enclosure, the total exhaust ventilation rate is the sum of the rate of all the batteries.

Natural Ventilation

Natural Ventilation may be by way of holes, grilles, or vents where airflow can pass by the battery system.

Ventilation mechanisms must be evenly spaced apart, outlets located in the highest part of the enclosure and inlets near the base.

In your Naturally ventilated enclosure, you will need to calculate the minimum size of inlet and outlet apertures which is determined from the following equation:

A = 100qv . . . 2.7.5.2

where

A = the minimum area of the apertures, in square centimetres

qv = the minimum exhaust ventilation rate, in litres per second (see Clause 2.7.3)

With natural Ventilation, an air velocity of at least 0.1 m/s is assumed to flow through the apertures.

For Further Ventilation Information

You can obtain further information from the Australian Standards document AS4086.2-1997.

Questions

Contact the Valen team for ventilation solutions on your next battery project.

Reference – * AS4086.2-1997 pages11-12 from SAI Global – Download the Document