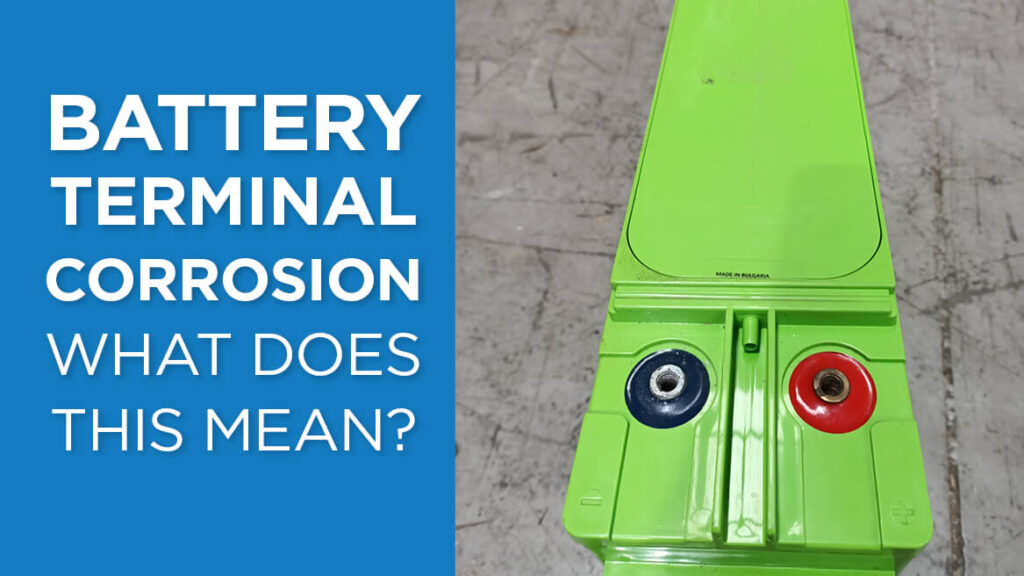

Battery Terminal corrosion what does this mean? We’ve all been there and understand it’s frustrating to get to site and see your battery terminals covered with corrosion.

In this article, the Valen team will provide everything you need to know about battery terminal corrosion on dry cell batteries (AGM, GEL).

We’ll outline why Battery Terminal Corrosion happens, how to prevent it and what to do with affected batteries.

What causes is battery terminal corrosion?

Terminal corroding happens to dry cell ba tteries due to the hydrogen gas being released from the battery acid, causing a chemical reaction with the metal terminals. Corrosion looks like a layer of white or green flaky built up on the terminals.

tteries due to the hydrogen gas being released from the battery acid, causing a chemical reaction with the metal terminals. Corrosion looks like a layer of white or green flaky built up on the terminals.

What causes battery terminal corrosion?

Common factors causing battery terminal corrosion can be;

– Overtightening the terminal bolts – Overtightening leads to a hairline crack around the terminal post, which allows the battery to gas. This gas then reacts with the battery terminal and causes corrosion.

– Plate growth – This comes from overcharging a battery or operating it at high temperatures, which causes the battery to vent. As hydrogen is a smaller atom than oxygen, it escapes first. This venting creates an unbalanced, negatively charged chemical reaction in the battery. As this occurs, it attaches itself to the positive plate and this build-up leads to plate growth. As the plate grows, it cracks the epoxy around the terminal and allows gas to escape rather than through the battery vent. As the gas escapes, it reacts with the battery terminal and forms corrosion.

How to Prevent Corrosion on GEL batteries?

Not everything is preventable; however, there are some steps to ensure corrosion is reduced and or prevented.

– Correct battery installation using a torque wrench to ensure the terminals are not overtightened,

– Regular maintenance: check the tightness of connections with a torque wrench, check the charging setting and make sure it’s not getting overcharged.

– Install batteries in shaded areas or if in a cabinet, make sure this has ventilation to keep the temperature from extremes

– Clean terminals on maintenance visits

– Ensure your charger has temperature compensated charging to accommodate for those high temperatures and prevent overcharging.

– Check out Valen OPzV Batteries with their sliding pole technology. This technology has been specifically designed for those high temp cyclic solar sites where plate growth is unavoidable.

Do you need to replace the battery if the terminals have corrosion?

Corrosion can affect the power flow from the battery, so it’s recommended to address this to get the most from your battery and increase its life. If battery terminal corrosion is picked up early, we would recommend cleaning this off, steps below;

- Make sure the battery is isolated (load is turned off) so the battery can be removed.

- Avoid touching with bare hands. If the corrosion is too thick the connections can’t be undone, use gloves and a wire brush to remove the majority of corroded material

- Now unscrew the connections and use a rag, apply a mixture of water and baking soda. This mixture acts as a neutralize to the acid.

- Scrub the baking soda mixture into the terminals using the wire brush.

- Clean off the mixture with the rag and let the battery dry completely (normally 24hours).

- Reinstall the battery and reconnect terminals and tighten. Now the load can be turned back on.

- Once the battery has been cleaned, it’s now time to work out what caused the corrosion and put measures in place to prevent it from happening again.

However, if the corrosion is deep-seated into the battery terminals, the cleaning process may not be effective, so we would recommend replacing the battery to ensure safety and the best efficiency.

The battery terminal has a tin coating over the copper to reduce the chance of corrosion. If the corrosion has damaged this coating, there’s a high chance you’ll see the corrosion again before long.

Conclusion

In conclusion, battery terminal corrosion is manageable and can be reduced to help reduce the need to replace batteries before time.

If you still have unanswered questions about terminal corrosion or specific questions for your site, please reach out to the Valen team or call 1300 734 253.

tteries due to the hydrogen gas being released from the battery acid, causing a chemical reaction with the metal terminals. Corrosion looks like a layer of white or green flaky built up on the terminals.

tteries due to the hydrogen gas being released from the battery acid, causing a chemical reaction with the metal terminals. Corrosion looks like a layer of white or green flaky built up on the terminals.