What causes VRLA Battery Failure? Valve Regulated Lead Acid (VRLA) batteries are the primary source of power for many applications; from Mobility Scooters and Cleaning Machines to mission-critical Communication systems – we rely on these batteries.

We all want to ensure longevity from our battery system, but first, we have to understand the reasons why VRLA batteries fail prematurely, what kills VRLA batteries?

In this blog post, the experts at Valen take a look at some of these reasons and ways you can prevent your VRLA batteries from failing prematurely.

Incorrectly Specified batteries

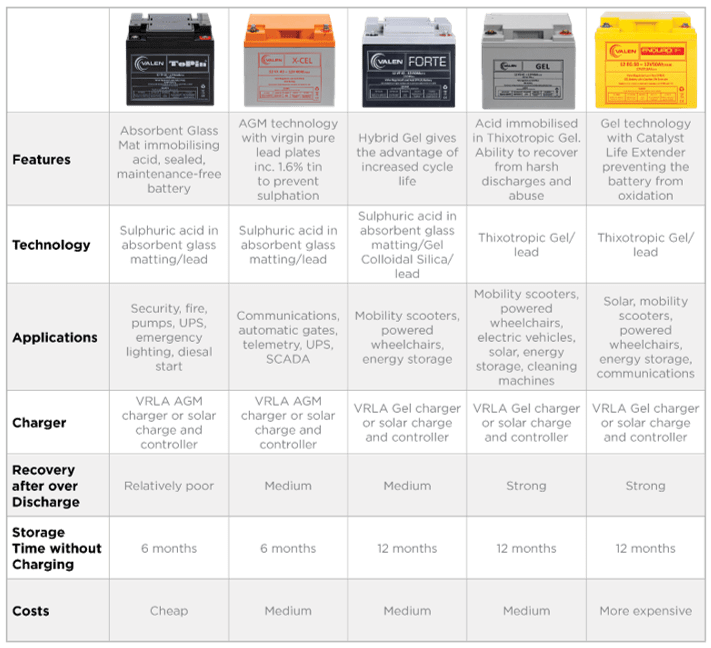

Specifying the correct battery technology based on the application is crucial. Different battery technologies are designed and manufactured for the demands of various applications.

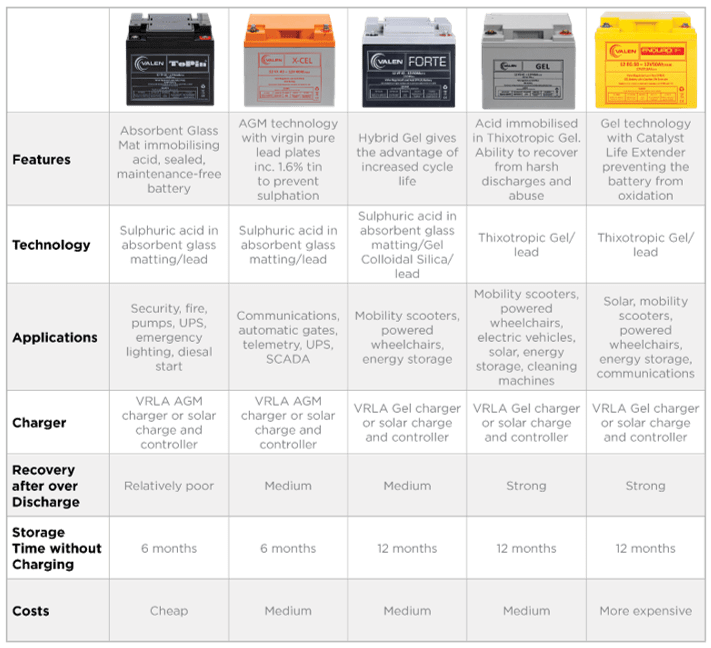

Each battery technology has its strengths and weaknesses, as shown below, based on Valen’s range of VRLA batteries.

What can you do about it?

- Speak to a VRLA battery supplier about your project details to decide which battery technology is best for your application.

- Do your research. Find e-books, blogs, etc. that go over different battery technologies benefits, features and applications.

High Temperature

Temperature plays a dramatic part in the accelerated failure of Valve Regulated Lead Acid (VRLA) batteries. Every increase by 8°C above 20°C halves the life of the battery. That’s a stunning statistic, especially in a hot country like Australia.

What can you do about it?

- Temperature monitoring

- Temperature-compensated charging systems

- An air-conditioned environment where available

- Adequate ventilation in your battery enclosure or room

- Catalyst Life Extender – using a battery with the Catalyst Life Extender which prevents battery dry out, allows that 20°C thresholds to be raised to 30°C.

Valen’s ENDUROX-CEL and ENDUROGEL range features the revolutionary Catalyst Life Extender.

Unequalisation

Unequalisation occurs when one or more battery cells falls out of line and become unbalanced. Unequalisation in time affects the whole battery system as it loses the ability to charge and discharge equally. Eventually, these failing cells drop out and fail, placing extra strain on the complete system, or swell up and got hot due to the extra pressure placed on them.

What can you do about it?

- Utilising an equaliser that sits across your battery strings will ensure that each cell is equally charged and discharged.

Click here to view Valen’s range of Battery Equalisers

- Periodic maintenance, including monitoring of individual battery cell voltage on maintenance inspections, is recommended to ensure that the system is running well.

Inadequate Monitoring and Maintenance

Prevention is better than cure! The best thing you can do is treat your battery banks with the appropriate care.

It is recommended to read and implement the battery’s Installation & Operation (I&O) manuals. I&O manuals will give you the relevant details, including detailed information on charge rates, storage and installation metrics explicitly based on the appropriate battery technology.

Ensure the correct battery is selected for the applications. Batteries are designed with specific functions in mind. For example, the Valen Gel range is ideally suited for applications such as Mobility Scooters and Solar systems.

Regular site visits are imperative to ensuring the battery system is running well. The I&O manual will detail the steps you need to complete an on-site visit.

These checklists include battery terminal torque settings, ensuring all connections are correct and tight, battery impedance (and discharge load testing where available), and more. Maintenance and monitoring of other equipment that affects the battery system are imperative as well.

Battery testing is essential to maintaining battery systems. There are a few ways you can carry these out. However, the recommended method and battery tester will vary on the application:

- Impedance testing is best for live circuit monitoring,

- Load testing is discharged load bank testing; and

- Online monitoring with reporting.

Incorrect Storage

Battery storage is significant to the life of the battery. It needs to be adhered to following the manufacturer’s Installation & Operation (I&O) manual as storage instructions will vary depending on the battery technology in question.

What can you do?

- Ventilation of the battery area,

- Regular charging of all batteries in storage:

- AGM batteries: recommended recharge is 3-6 months,

- Gel batteries: recommended recharge is 6-12 months; and

- Lithium batteries: recommended recharge is 18 months.

- The temperature of the battery area; and

- Ensuring the area is danger-free – free from elements such as fire, sparks or water.

Need some extra advice on how to prevent battery failure? Want to know which battery you should install?

Reach out to the team at Valen who are happy to look at your system and recommend the correct battery for your application and installation.

For more expert help and advice, talk to one of our knowledgeable team members by calling 1300 734 253. Or simply click here to contact us.