How to manage deep cycle batteries in hot weather? When the weather starts heating up, the team at Valen often get asked this question.

The answer depends on the system specifications the battery is being installed into and the battery technology that is chosen for the system.

For deep cycle VRLA batteries, the most common operating temperature specified with design life is 25°C. However, the actual design life is very much dependent on the day-to-day operating temperature the battery is exposed to.

In this blog, the battery experts at Valen take you through the impacts that hot temperatures have on deep cycle VRLA batteries as well as solutions for optimising the battery storage conditions in extreme temperatures. We’ll also take a look at how Lithium Phosphate batteries perform in hot conditions.

What impact do high temperatures have on VRLA DEEP Cycle batteries?

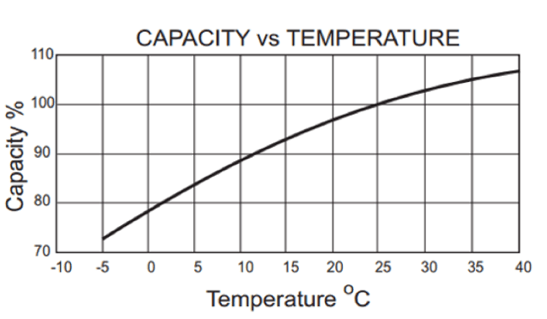

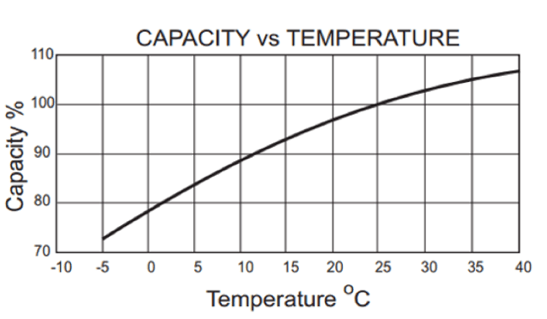

As shown in the graph below, extreme heat won’t have any negative impact on the amp capacity of a deep cycle VRLA battery.

In fact, the amp capacity of a deep cycle VRLA battery decreases significantly with each degree under the normal operating temperature.

However…

Every 8°C rise in ambient temperature above the normal operating temperature will halve the design life of a battery.

So for example, a VRLA battery with a design life of 10 years with a specified normal operating temperature of 25° C would only last for 5 years if placed in an operating environment of 33°C.

The impacts of hot temperatures on deep cycle VRLA batteries are of particular concern in Australia where temperatures in the Summer can reach over 50°C in certain remote areas. Managing operating temperatures becomes even more crucial when batteries are enclosed in cabinets without the correct ventilation and placed in direct sunlight.

Methods for optimising deep cycle batteries in extreme high temperatures

There’s good news for those who need to install battery systems in hot, remote areas.

It’s possible for a VRLA battery to function and operate reliably in such conditions. Careful consideration does need to be given to the overall system design and a detailed understanding of the individual battery specifications is required.

There are two main methods for optimising the lifecycle of a VRLA battery in hot operating temperatures:

#1 – Adjust the system design to maintain normal operating temperatures

Cooling measures can be incorporated into a system design to ensure a VRLA battery achieves the correct capacity and maintains an optimal design life.

If the day-to-day expected operating temperature is going to be high, the following cooling mechanisms can, potentially, be added to the battery storage or cabinet:

- Air conditioning

- Fans

- Sun shields

- Insulation

- Cross ventilation

To check if these cooling mechanisms are a viable option for your system, please contact the team at Valen.

#2 – Temperature compensated charging for deep cycle VRLA batteries

It’s extremely important to ensure VRLA battery chargers have temperature compensation functionality, particularly in hot temperature scenarios. This will ensure the batteries are not over-charged.

As battery internal temperature rises, the chemical reaction increases, which in turn lowers the battery voltage. A charger without temperature compensation will detect this as a discharging battery and, as a result, will attempt to charge the battery. In actual fact, the battery may be fully charged and just hot from external factors thus potentially resulting in a battery failure.

The additional charge coming into the battery as a result of this battery charger not having temperature compensation is then converted into heat. This leads to the battery being damaged from over-charging.

During over-charging, as one cell within the battery warms up, it will start affecting the cells on both sides of it. Thermal runaway occurs when the heat from one over-charged cell affects the next cell and results in it being damaged as well.

Should batteries be subjected to higher temperatures for long periods of time, the battery cells will start to dry out resulting in plate sulphation and premature battery failure.

Along with this, over-charging can cause the battery to swell and leak electrolytes out of the battery vents.

A “smart” battery charger with temperature compensation charging will feature a sensor that will automatically regulate the charge voltage so as to protect the battery.

This functionality will ensure a battery is always properly charged and maintained, no matter how hot the operating conditions become.

To ensure you are using a “smart” battery charger in your system, please contact the team at Valen.

What about Lithium Phosphate batteries in hot temperatures?

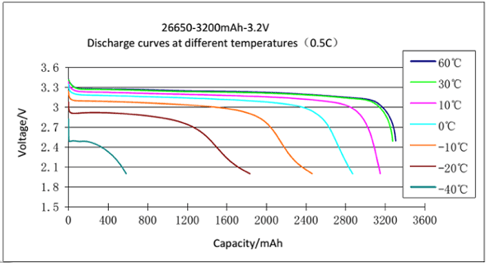

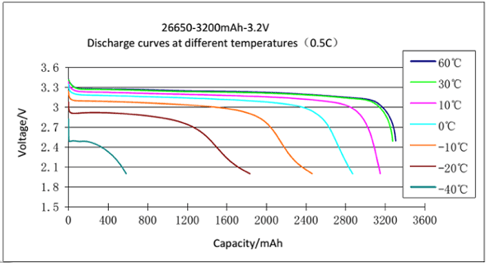

A correctly designed Lithium Phosphate battery with an inbuilt BMS (Battery Management System) protection has the ability to out-perform VRLA batteries in high-temperature environments.

As shown in the below graph, Lithium batteries can reach operating temperatures of up to 60°C with basically no limiting of the capacity. This is a major advantage in comparison to VRLA batteries. As stated above, VRLA batteries lose half their design life with every 8°C increase in temperature over 25°C. So it’s easy to see why Lithium batteries are the superior choice for hot operating environments.

Quick Case Study

In 2013, Valen first had experience with installing Lithium batteries in solar-powered systems in Northern Western Australia where the average daily temperature is around 40 degrees.

The systems had AGM VRLA batteries previously installed which were only lasting 1 year before failing.

The main advantages the client required from the Lithium batteries were resistance to heat, resistance to corrosion (caused by a combination of heat, humidity and battery emissions) and the low weight of Lithium batteries.

The customised Lithium batteries Valen designed and supplied for the systems back in 2013, are still in operation as of today in 2019. This goes to show how reliable the performance of Lithium technology is in hot operating environments.

Need advice on which battery technology will best suit your high-temperature system? OR what protections you should put in place to guarantee maximum battery life in hot temperatures?

The team at Valen are here to help, simply click here to get in touch. Or you can schedule a no-obligation 15-minute phone consult with one of our battery experts to chat about your project and battery needs.