Optimising Power Reliability: Solving Stewart Electrical’s Energy Challenges

Stewart Electrical, a well-established electrical services company in New Zealand, specialises in providing dependable power solutions for remote and demanding environments. With a reputation for tackling complex energy challenges, they found themselves facing increasing power demands at one of their sites, which exposed the limitations of their existing infrastructure. Seeking a more robust and efficient system, Stewart Electrical partnered with Valen Power to implement a long-term solution tailored to their evolving needs.

System Limitations

Over time, the Hutt and Wainuiomata / Orongorongo water collection site’s power demand had increased due to the addition of new radio equipment. These changes led to an imbalanced and undersized power system that struggled to meet the load demands. The existing system, which relied primarily on solar panels, had backup power provided by an LPG generator and methanol fuel cells. However, the frequent use of the generator to supplement the insufficient system meant that LPG bottles needed replacing every two weeks, incurring additional costs. The methanol fuel cells were also experiencing increased wear and tear. Compounding the issue, the system lacked proper monitoring capabilities, making it difficult to track power usage and system health.

System Overhaul and Enhancement

Valen Power stepped in to assist Stewart Electrical with a comprehensive, customised energy solution. Our team first took the time to fully understand the current load profile and Stewart Electrical’s future needs and goals for the site. It became clear that the client’s primary goal was to ensure a more efficient system and reduce reliance on the LPG generator, only using it sparingly.

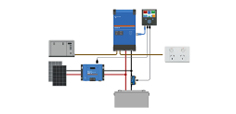

With this in mind, Valen designed, built, and tested a full replacement system, which included:

- Three strings of long-life lithium battery modules for reliable energy storage.

- Additional solar panels to increase the site’s energy capture from renewable sources.

- Inverter chargers to seamlessly manage the power distribution across the system.

- A dual-redundant design for enhanced reliability and system resilience.

Furthermore, we upgraded the system’s control and monitoring capabilities, allowing Stewart Electrical to remotely monitor various data points, including temperature controls, door alarms, fuel levels, and even the ability to remotely start the generator.

Results and Impact

The results were immediate and impactful. With the new system in place, Stewart Electrical experienced a significant reduction in costs related to LPG bottle replacements and generator call-outs. Equipment that had previously been turned off due to power constraints could now be recommissioned, providing greater operational efficiency. Additionally, with enhanced monitoring, Stewart Electrical gained better visibility and control over their energy use, ensuring that the system could meet current demands and accommodate future growth.

By partnering with Valen Power, Stewart Electrical now has a future-proof energy system designed to handle increased load demands, with reduced reliance on costly backup power. The solution provided not only cost savings but also peace of mind, knowing their system is capable of supporting their operations well into the future.