How to meet battery compliance in fire protection systems. It is essential that technicians, and anyone attending site, stay safe around fire protection systems and the supporting batteries. After all…these systems are there to protect lives and assets.

So what do you need to do to ensure that site personnel and members of the public are kept safe?

It is always best to be aware of relevant industry standards as they will outline any areas of concern and ensure you are compliant if followed.

In this blog post, the experts at Valen take a look at relevant fire protection system standards as well as important factors for ensuring battery compliance.

What Standards do I need to be aware of?

The Building Code of Australia requires fire hydrant and sprinkler systems to be installed in accordance with the following standards:

- AS 2419.1-2005, Fire hydrant installations – System design, installation and commissioning

- AS 2118.1-1999, Automatic fire sprinkler systems – General systems

- AS 2118.4-1995, Automatic fire sprinkler systems – Residential

- AS 2118.6 – 1995, Automatic fire sprinkler systems – Combined sprinkler and hydrant

All of these standards require fire compression-ignition (diesel) pump sets associated with these systems to be installed in accordance with AS 2941-2008 (Fixed fire protection installations – Pumpset systems).

What type of batteries should be used in fire protection systems?

AS2941-2008 requires fire system batteries to be in compliance with AS4029. This standard covers 3 types of batteries:

- Vented type batteries such as those used in automotive applications

- VRLA type batteries – such as AGM (Absorbent Glass Mat)

- Pure lead positive plated types

However, Fire Protection Association Australia (FPA) take this one step further and officially recommends that;

- Batteries are always correctly maintained

- Batteries are of the VRLA AGM type

- The correct float charge voltage is used

AGM batteries are ideal for fire systems as they do not require maintenance of the electrolyte fluid and are sealed (except for the inclusion of a safety pressure relief valve to discharge gas build-up). The technology adopted by AGM batteries produces water as a by-product of the chemical reaction process.

This means that there is no requirement to maintain electrolyte levels manually and the risk of “explosion” that results from batteries drying out through depletion of electrolytes is eliminated.

Float charge voltage is commonly recommended to be between 13.0 VDC and 13.8 VDC at 26.70C; however, each manufacturer will have a specific charge voltage for their batteries.

It is extremely important that the float charge voltage of the battery is set in accordance with the battery manufacturer’s requirements to prevent incorrect charging and gas build-up, which may result in an “explosion” risk.

How often should I test the batteries? And how do I test them?

How often fire system batteries need testing will depend on the specific fire system being tested. Testing may be required anywhere between monthly, six-monthly or yearly. However, the batteries in these systems are normally tested at least every 2 years.

AS1851.2012 (Australian Standard for ‘Routine Service of Fire Protection Systems and Equipment) requires the batteries to be tested to 20% of their capacity using a large constant current discharge tester. This allows for fast recharge and does not drain the battery unnecessarily.

For more information on the proper method for testing battery capacity, check out our blog on how to correctly conduct load testing on batteries used in fire systems.

Do I need to install battery warning stickers on-site?

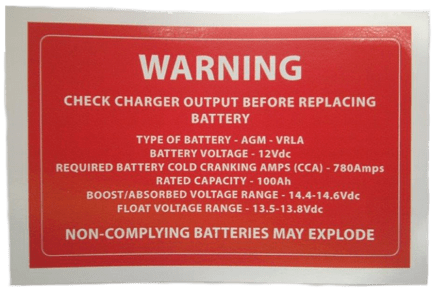

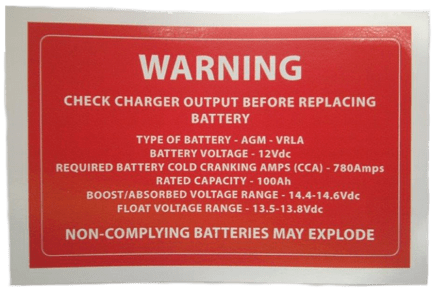

Clause 3.13.6 of AS 2941-2008 requires a warning sticker to be fixed adjacent to batteries serving fire pump sets. See the example sticker below.

What else do I need to be aware of concerning safety and compliance?

We recommend that the following points are kept in mind when working with the batteries in fire protection systems;

- Appropriate PPE (Personal Protection Equipment) is worn especially adequate eye and clothing protection when installing or maintaining fire systems

- Physical check of the batteries should be done prior to testing and any batteries with defects or damage should be isolated and replaced immediately

- When starting the fire protection system up, ensure extra care is taken

- Ensure there are no ignition sources within the battery area.

- Always use AS4029.2 compliant batteries. If the batteries are not marked complaint, check with the supplier

- WH&S rules must be adhered to when performing maintenance on fire system batteries.

Want to learn more about fire system battery compliance? Talk to the experts at Valen

We are proud to offer the highest level of technical support and training to our fire systems clients.

Our Valen Topin AGM battery range has been used within the fire systems industry for over 15 years. In that time, these batteries have become the go-to, trusted brand for many technicians. The range is SSL approved and AS 4029.2 compliant.

To talk to one of our knowledgeable team members about your particular fire system, simply click here to get in touch.